-

Flat Rolled Product

Flat Rolled Product

Known for quality, commitment and delivery, our unit is having its captive foundry, holding furnaces and casters for making quality products ranging from 0.009 mm to 6.00 mm thickness.

We manufacture a wide range of aluminium alloys that include – AA 1XXX, 3XXX, 5XXX, and 8XXX. We are the first choice of customers of various manufacturing segments like Architectural, Electrical, Electronics, Façade, Solar, Insulation, Roofing sheets etc.

TWIN ROLL CASTERS

COLD ROLLING MILL

FOIL MILL

Quality Accreditations

Plain Sheets & Coils

Our cold rolled sheets and coils not only have uniform and bright surface finishes, but also meet all international standards for dimensional tolerances and metallurgical properties. Other than our standard specifications, we can also supply customized products to cater to the customer’s exact requirement. Our aluminium plain sheet and coil are majorly used for various applications.

END – USE APPLICATIONS

ARCHITECTURAL

TRANSPORT BODY

FAN BLADE

GENERAL ENGINEERING

MARINE

PRINTED CIRCUIT BOARD PANEL

ELECTRICAL & ELECTRONICS

INSULATION

CEILING PANEL

DISH ANTENNA

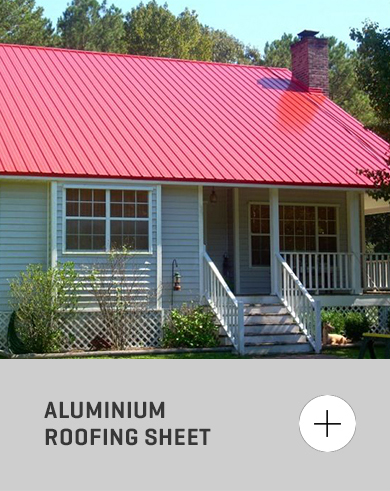

Aluminium Colour / Bare Roofing Sheets

Our “Forever” aluminium roofing sheets are manufactured to last for generations. We manufacture roofing sheets in bare as well as coloured form with RMP, SDP and PVDF coating. Our “Forever” roofing sheets are available in various profile shapes, such as industrial troughed (trapezoidal), circular corrugated, and tiled. Aluminium roofing sheets are the preferred choice for roofing applications because it is light in weight, corrosion resistant and has a very high resale value compared with other roofing solutions like galvalume and asbestos roofing sheets. We can supply Aluminium roofing sheets from 0.40 mm thickness to 1.60 mm thickness in 1100, 3003, 3103 and 3105 alloys for various applications

END – USE APPLICATIONS

INDUSTRIAL SHED

INSULATION AND WALL CLADDING

RESIDENTIAL ROOF

Product detailed drawing

House Foil

Our “Safewrap” house foil is available in various specifications to meet all of our consumers’ requirements. House foils is being used extensively for food packaging. This product is annealed under our high accuracy gas fired furnaces, and then packed in seaworthy packaging after being hygienically re-wound into easy-to-handle cut reels ranging from 9 meter to 72 meter length. Presently, we are supplying this material in alloy 8011.

SPECIFICATION:

Chequered Sheet / Pattern Sheet

Patterned sheets are primarily being used for flooring as they are anti-skid due to treads. Our pattern sheets are having a high strength to weight ratio and are also having good welding and forming properties. We supply this product in two different designs – Five Bar and Diamond. Apart from standard specifications, we can supply pattern sheets in customized alloys and sizes. Our pattern sheets are catering various segments like

END – USE APPLICATIONS

GENERAL ENGINEERING

FLOORING SHEET FOR BUS, TRUCKS, RAILWAYS ETC.

SPECIFICATION:

Multi Slit Coils

Jindal Aluminium’s multi-slit coils are very well suited to be used in heat exchangers and transformers. Made under our strict quality control systems and with very cutting-edge equipments, our material meets all the domestic and international standards in terms of build-up, tolerances and other specifications. We can supply this product in various alloys such as 1050, 1060, 1100, 1200, 3003 and 3103.

SPECIFICATION:

Slugs And Circle

We offer this product in a wide range of sizes, as per our customers’ specific diameters and thicknesses. They use our circels and slugs to manufacture pressure cookers, non stick cookware, cans etc. We use a high speed punching line with an automatic stacker to protect the surface finish of our products and to ensure top quality and durability. Our circles and slugs are being used for various applications.

END – USE APPLICATIONS

UTENSILS

AGRICULTURAL & AEROSOL CAN

DEODORANT BOTTLE

SPECIFICATION:

SPECIFICATION: CIRCLES

Product Catalouge

Closure Stock

Our product is made through our highly automated mills for getting the precise tolerances for pilfer proof caps so that our customer can run this material on their high speed machines, uninterrupted, and get a good yield. Our closure stock is manufactured by using 8011 alloys, since this is having the desired strength and drawability. Our product is suitable for various applications like

END – USE APPLICATIONS

VIAL CAPS

LIQUOR BOTTLE CAPS

FRUIT BOTTLE CAPS

SYRUP CAP

SPECIFICATION:

Aluminium Litho Coil

Considered a premium product made out of aluminium, litho coils have been developed by Jindal Aluminium under closely controlled parameters. Our coils are processed in a dust free environment and are tension levelled to achieve the desired flatness. The gauge and flatness are controlled by our Achenbach AFC installed in our cold rolling mill which ensures our products meet all required standards. This product is mainly supplied in alloy 1050 and 1060 aluminium alloys for offset printing plate applications.

SPECIFICATION:

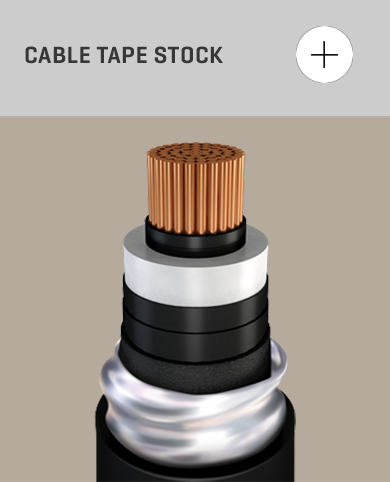

Cable Tape Stock

Our cable tape stock meets all domestic and international standards and is being used by all of the major cable manufactures in India. Being made from pure ingots and processed through our latest equipments, our product are having excellent UTS, elongation and length requirements that meet the needs of the cable industry.

SPECIFICATION:

Aluminium Composite Panel Coils

This product is considered a premium product and is being used for architectural application. Our aluminium coils which, are produced through our highly automated CRM and equipped with AFC / AGC, are “table top flat” . This meets the stringent and critical requirements of this segment. The product comes with a bright finish, excellent dimensions and high quality. The product also has excellent strength and formability.

SPECIFICATION:

Bare Foil

Aluminium Foil is one of our focused products, and we are manufacturing our foils by taking the utmost care. As foils are being used for various critical segments, we ensure our products exceed the quality expectations of each and every one of our customers. Our foils are processed on our hi-tech Achenbach foil mill to ensure all technical parameters meet the specifications i.e. surface finish, thickness and width tolerances. We supply this product in various widths and tempers as per the industry / customer requirement. Presently, we are offering foil in alloys like 1100, 1200, 1050, 1060, 3103, 8006 and 8011 for various applications like

END – USE APPLICATIONS

TAGGER FOIL

SEMI RIGID CONTAINER (SRC FOIL)

AIR FILTER

TOBACCO PACKAGING / FLEXIBLE PACKAGING

FOIL TAPE

CANDLE BASE

LAMP CAP

SPECIFICATION:

Others

Being a light weight and modern metal, usage of aluminium is not restricted to above segments only, but it is used extensively for many other products and segments such as ladders, signages, muff tubes, cooling towers, bus shelters, cycle frames, turbines, green house solutions, industrial fans, blowers, antennas to name a few. Accordingly we are also supplying to all such segments being an associate of almost all the leading companies using aluminium products, in India and globally.

Jindal Aluminium constantly strives to deliver products to customers, the quality of which exceeds their expectations and at a price which creates value for their money. “Customer delight” has been our motto since our inception and to achieve this, we have competent and fully trained teams who ensure that all of the high expectations of our customers are taken care of. Right from the beginning of enquiry to the delivery of material, our teams ensure that the material is delivered in a time-bound manner for our prestigious international customers.

The international customers are asked in detail about the end application, and based on their requirement technical suggestions are given, if necessary, to alter the design, thickness, alloy, coating, mode of packing, etc, to ensure trouble-free use of our product/s at an economical cost. Our superior quality products meet the intricate requirements of all segments of customers like industrial users, builders & fabricators, automobiles, wind & solar energy generators, insulation, etc, to name a few. We have an array of actual users who have been associated with us for decades. We also have an extensive dealer network spread across the globe, to ensure that our products are made available to the end users.

jrmexport@jindalaluminium.com

Jindal Aluminium leaves no stone unturned to keep its domestic customers satisfied. To ensure that our domestic customers get value for their money, we understand their actual requirements, and accordingly give suggestions for improvement, wherever needed.

Having a world-class manufacturing facility for producing superior quality flat rolled products by using modern equipments, we make products that are widely acceptable for various applications like – architectural, transportation, electrical, electronics, insulation, roofing, foils, cookware, etc. To reduce the lead time and to give uncompromising service, we have a dedicated marketing team.

jrminfo@jindalaluminium.com

Jindal Aluminium ensures that our quality products are available across the country. To facilitate the same, we have an extensive dealer network which ensures that our products are easily available to end users. Our exclusive dealers can be contacted as per below details –